Stellarators

Stellarators are perhaps the most promising alternative fusion devices to mainstream tokamaks with the possibility for steady state operation and no danger of damage from plasma loss in disruptions.

The stellarator was invented at Princeton in 1951, pre-dating tokamaks, but after the big success of the T-3 tokamak in 1968, which had much longer confinement times than existing stellarators, most fusion research became focussed on tokamaks. In 2022, 11 stellarator and similar devices were in operation and since 2019 several new private fusion companies designing stellarators have found funding showing a revival of interest in the concept.

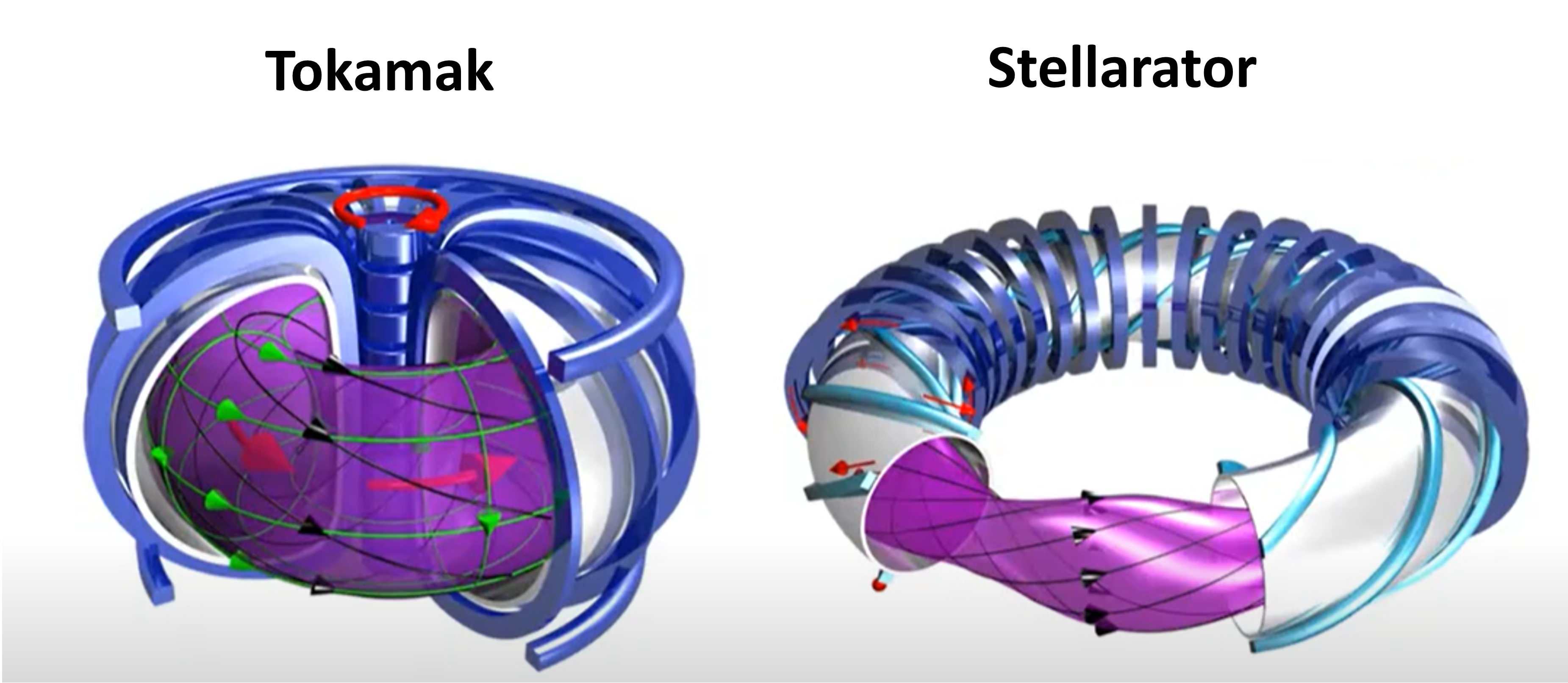

Stellarators are toroidal magnetic confinement devices with a different magnetic configuration from tokamaks as indicated in figure 1. In the tokamak, the plasma current generates the poloidal magnetic field which rotates the magnetic field lines around the toroid to avoid charge separation and loss of plasma confinement. In the stellarator, a complicated configuration of magnet coils provides a field configuration which directly avoids charge separation and so requires no circulating plasma current.

Figure 1. The configuration of a stellarator compared with a tokamak. In a tokamak the field of the toroidal coils is modified by the circulating plasma current. The field configuration of the stellarator requires no circulating current for confinement stability, so simplifying the device operation and allowing steady state operations.

The complex twisted magnetic field in a stellarator is the riddle for the success of a stellarator. Different versions of stellarators have diverse options for coil configuration and so resulting fields. Many stellarators have individual coils with non-planar shapes, such as that in figure 2, which are difficult to manufacture. Advances in stellarators, towards increasing plasma confinement times, have focused on optimizing the field configuration and coil shapes.

Figure 2. A coil of the stellarator W7-X design, showing the complex non-planar shape required to form the required twisted magnetic field.

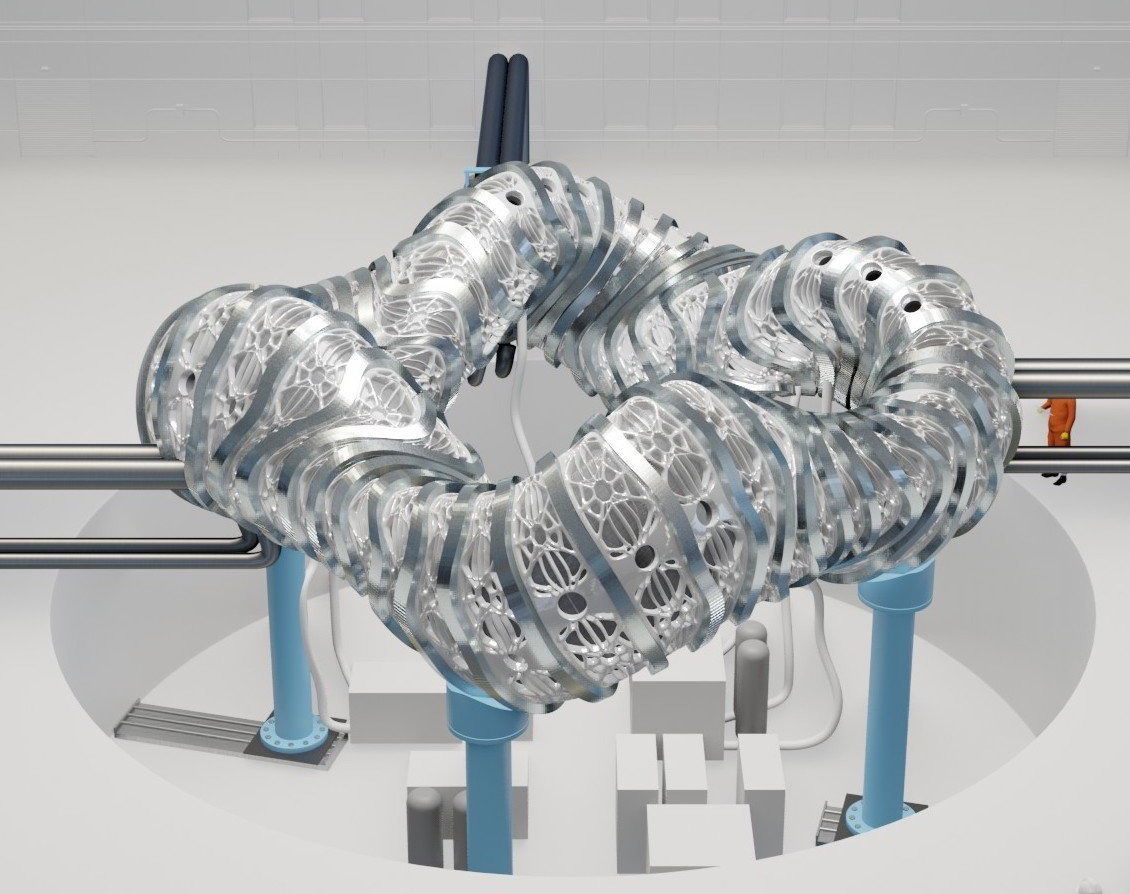

At present the Wendelstein 7-X (W7-X) stellarator in Germany, shown in figure 3, is the world's largest stellarator device. It has a major radius of 5.3 m and a minor radius of 0.5 m, with a vacuum volume of 30 m3 and a magnetic field of 3T. Since the start of operations in 2015, the machine has produced better and better storage results and in 2023 demonstrated a plasma discharge for eight minutes.

Figure 3. Wendelstein 7-X stellarator during construction in November 2011. The outer container containing all the magnet coils is 16 m across.

Private Fusion Companies developing Stellarators

Seven private fusion companies with plans to build stellarators had declared funding >$5 million in 2023:

- Type One Energy , based in USA, founded 2019, funding $30 million.

- nT-Tao , based in Israel; founded 2019, funding $30 million.

- Thea Energy, based in USA, started 2022, funding $20 million.

- Renaissance Fusion, based in France, started 2020, funding $20 million.

- Gauss Fusion, based in Germany, founded 2022, funding $8 million.

- Proxima Fusion, based in Germany, started 2023, funding $8 million.

- Helical Fusion, based in Japan, founded 2021, funding $6 million.

Type One Energy

Type One Energy is planning a 500 MWe output stellarator. Their website states: "Members of the Type One Energy team united after they demonstrated the benefits of other optimized stellarators. Responsible for important aspects of the HSX and W7-X stellarators, their experiences revealed excellent agreement between theory and real-world design. Today, we are applying these lessons to design a grid-ready machine."

The website does not provide many technical details of their design beyond the image of the planned stellarator in figure 4. The website does give an overview of their concept which is copied into figure 5. The "No Miracles Required" remark is not further explained but likely implies that some of their competitors in the fusion start-up field, in particular those companies with aneutronic and pulsed devices, do need miracles to succeed.

Figure 4. Type One Energy stellarator concept.

Figure 5: Type One Energy: website summary of advantages of their stellarator technology. The same advantages will apply for all the other stellarator start-ups.

nT-Tao

The nT-Tao company is planning to build small stellarators with power output 10-20 MWe which fit in a shipping container as in figure 6.

Figure 6: nt-Tao small stellarator inside a shipping container.

Thea Energy

Thea Energy plans a stellarator with > 200 MWe power output. The company spun out of Princeton University and Princeton Plasma Physics Laboratory, where the stellarator was first imagined in 1951.

A schematic of the design is shown in figure 7. A driving feature of the Thea design is to simplify the coil design this will be done with a set of planar toroidal coils and in addition a large number (600) small correction coils which impose the twisted stellarator field configuration but also allow 3D control and even modification of the basic design field.

Figure 7. Helios Stellarator of Thea Energy

Renaissance Fusion

The declared objective of the Renaissance Fusion company company is to build a 1000 MWe fusion power plant.

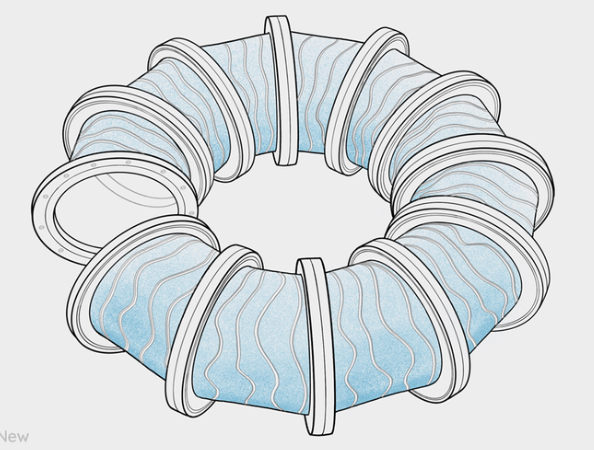

The stellarator design, shown in figure 7 consists of several discrete cylinders joined together to form a torus. Each cylinder has a layer of REBCO superconductor deposited on the surface which is then laser machined to define the path for the circulating current which forms the magnetic field, as illustrated in figure 8. While this idea appears superficially brilliant, it is obviously very complicated to manufacture. In addition the interfaces between cylinders would need to be complex and would inevitably produce significant local distortions in the magnetic field. The mechanical support around the coils necessary to maintain them in place would be a significant structure which is missing from the simple picture in figure 7.

Figure 7: Renaissance Fusion stellarator design discrete cylinder joined ate locations to form a torus. Each cylinder has a layer of REBCO superconductor deposited on the surface which then has laser ablated groove to form the current conduction paths.

Figure 8: Renaissance Fusion, manufacture process of superconducting coils on the surface of a cylinder.

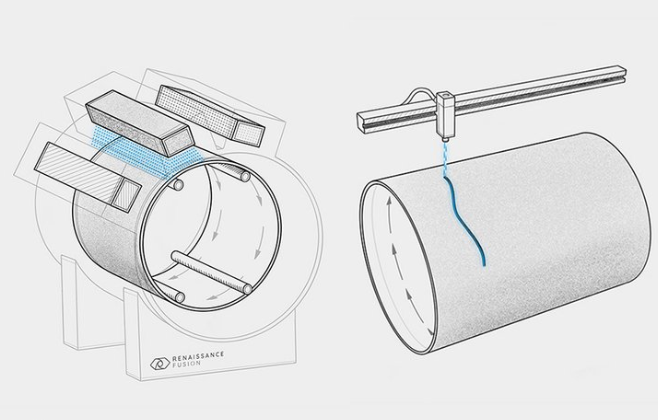

Another superficially brilliant but extremely difficult idea of Renaissance Fusion is the liquid metal first wall and blanket, the principles of which are shown in figure 9. Again, although this seem very clever it obviously has a great many technical challenges and would take a big development effort to make it work in practise.

Figure 9: Renaissance Fusion, Liquid metal blanket concept. The liquid metal flows from top to bottom, split in two halves, under the influence of gravity, G . An electric current, j , is carried with the liquid metal in the two half cylinders. With the magnetic field along the axis of the cylinder a j x B force pushes the liquid metal to the wall of the cylinder.

Gauss Fusion

Gauss Fusion was founded in 2022 and in January 2024 decided to concentrate on the development of stellarators. Few technical details are available of the company website.